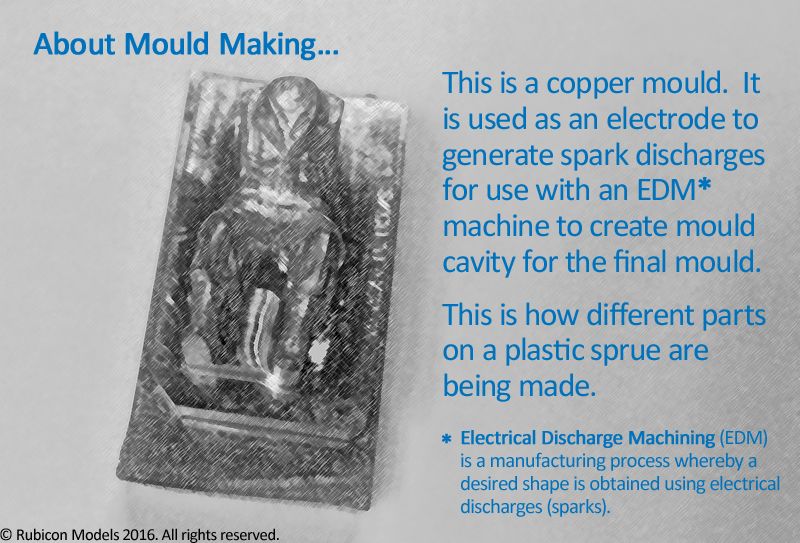

For those who might want to know how our plastic moulds are made... You can google "EDM Machine" for related video as material of interest.

The cooper mould that is used as an electrode comes from either our 3D drawings or digital sculpting software.

In most cases, we are using two part moulds, hence no undercuts and 90 degree angles are allowed for best results. There is a lot of work put into the design other than just making the 3D model. Not everything is done by machine, you still need experienced mould makers to fine tune your moulds after all the machining had been done to get that crisp details.